how does vapor honing work

Before you start the cleaning process you need to pick the type of abrasive youll use to clean your part. Vapor honed has two common meanings.

Vapor Honing Technologies Lilhonda Com

Using a fine glass bead slurry mix with 25-60 psi 37 cfm this is a high volume low pressure process that gets down into the fine areas removing any dirt grime rust or corrosion without removing any metal.

. Abrasive selection is made based on desired surface roughness or aesthetically desired finish. Does honing a knife remove material. Pressurized air blasts the mixture of water and abrasives at the surface of the part removing coating or other contaminants.

Vapor Honing often known as wet blasting is a technique used to polish precise surfaces. Client provides the parts and completed parts are returned in 30-45 days. To remove imperfections such as heat treat scaling you add fine abrasives to the water then sprayed onto the material at great speed.

What is vapor honing. Vapor honing is a finishing process that utilizes water and various types of fine media to restore parts to OEM finish. A honing rod on the other hand maintains that sharpnessit offers a quick fix by realigning the existing edge.

Vapor honing has many advantages such as being dust free preserving the surface finish of the part and creating a. Vapor honing also known as vapor blasting wet blasting or wet honing is a process that mixes an abrasive media with water to create an unparalleled finish and is much gentler on parts than acid baths or sandblasting. Vapor Honing Technologies Lilhonda Com Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa Vapor Honing Jim S Workshop Vapor Blasting.

Are favorite application is carbs for the finish it provides. Contrary to the conception most people that come through the shop have a honing rod steel is not a sharpener it does not remove any material from you knife. Instead of dry abrasive media used in sandblasting it uses a combination of water compressed air detergents with finer and gentler media to remove oxidized metal and corrosion.

The more proper one is an aspirated water as in a common blast cabinet except it is water instead of grit. Combining water and abrasive together forms a slurry which is propelled at the part surface using compressed air. Vapor honing uses water and abrasive flowing across the surface to scrub away contaminates rather than directly impacting the surface damaging and removing material.

A honing rod realigns the edge of. What is Vapor Honing. With water serving as lubricant the pressurized slurry mixture wont scar heat or warp the original surface of the part allowing even delicate internal engine components to be vapor honed.

It leaves a smooth satin finish and is much more gentle to the surface than dry sand or glass bead blasting. A very tiny abrasive can be added. Using a combination of compressed air and a flow of water borne abrasives this process gives a smooth and fine finish unlike dry blasting it leaves no damage to your parts.

Vapor honing is a low pressure wet blastin g process that safely cleans restores parts leaving a nice finished surface. Get green without paint. Vapor honing can refinish plastic and metal as well but you have to decide if this process is right for you.

Vapor blasting goes by many different names. On aluminum it leaves a finish that looks almost like paint. The key to vapor blasting is that the finish is produced through the flow of water borne abrasive giving a finer finish due to the flushing action of the water.

Its perfect for restoration work because it makes the metal surface look like new but does not remove metal like. The second is a pumped slurry with air added to create a more aggressive hone action. Pressurized water and abrasive are combined into a slurry.

Looking good and doing good with molded-in- metallic engineering resins. Vapor honing is a wet blasting process which uses very fine glass beads and water under air pressure. Vapor Hone services- We do this work hourly.

How Does Vapor Blasting Work. Vapor honing or sandblasting since it is completed after tool texturing can reduce texture definition causing rejects. Vapor honing also referred to as vapor blasting or wet blasting is a surface refinishing process used to clean and restore surfaces.

How does vapor honing work Tuesday March 1 2022 Edit. While it can handle a wide variety of materials it gives a excellent finish aluminum zinc brass and magnesium. Makes your old parts look like new.

Vapor honing can be used on almost any surface found on a motorcycle or car including gloss plastic. Vapor honing is also a great choice for removing very tiny scuffs and tool marks as well as for applications that need a satin-smooth finish. This will also add a small amount of tiny abrasive.

How Does Vapor Honing Work. No media is impregnated into the component nor is there any dust created by the break-up of media unlike dry blasting where the finish is produced by sheer force of media impact.

Rust Removal With Vapor Honing Vapor Honing Technologies Youtube

What Is Vapor Blasting Answering Your Wet Blasting Faqs

Vapor Hone 1000 Wet Blasting Equipment Wet Cabinet Made In The Usa

Vapor Honing Blasting Superfly Garage

Vapor Hone Up And Running Bike Builds Motocross Forums Message Boards Vital Mx

Vapor Blasting Services Wet Blasting Vapor Honing Technologies

A Simple Introduction To Vapor Honing Issuu

Vapor Blasting Cast Iron Using Crushed Glass Vapor Honing Technologies Youtube

Micro Vapor Hone Benchtop Vapor Hone With A Small Footprint

Vapor Honing Services What Is Vapor Honing And Does It Work

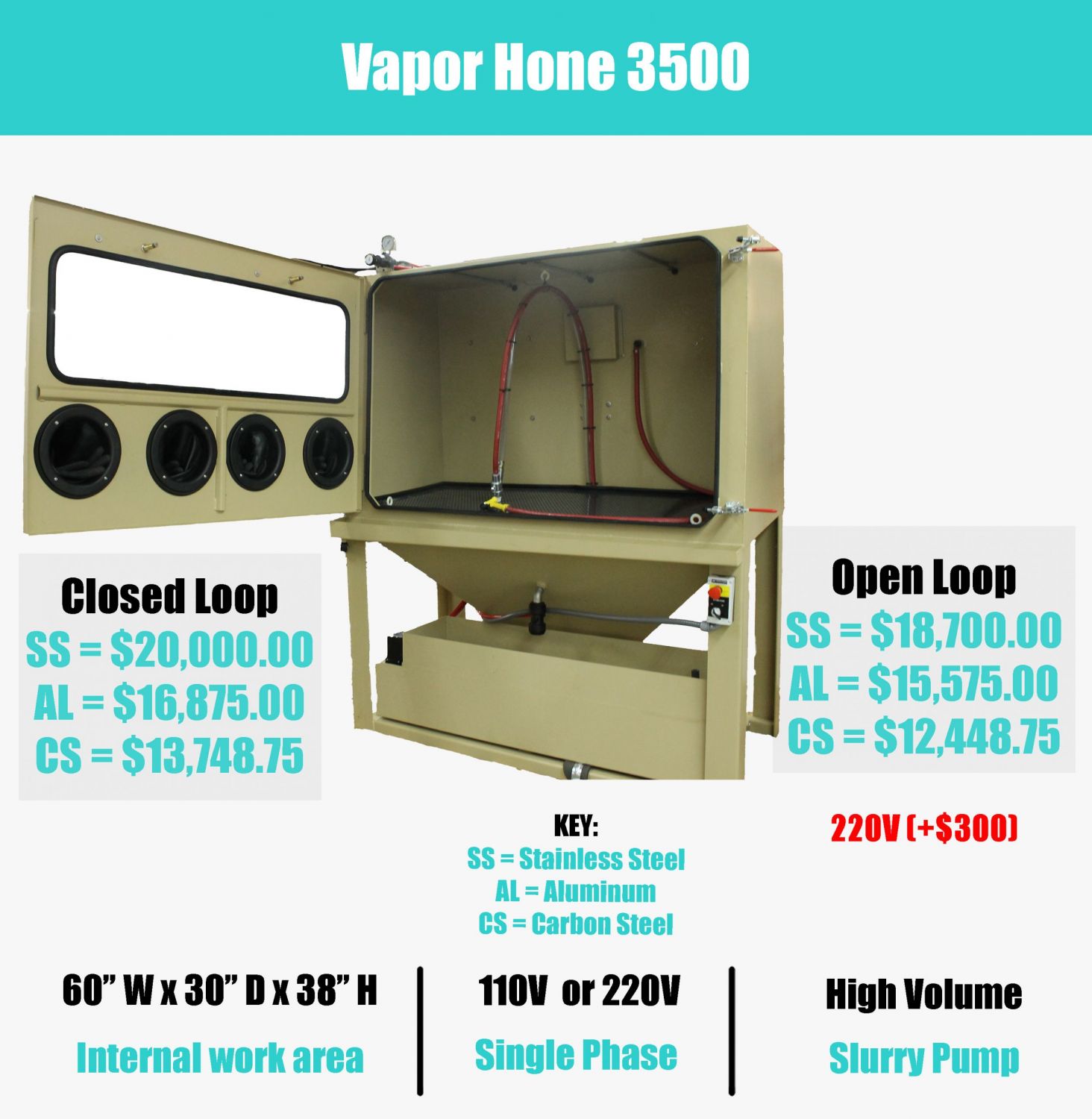

Vapor Hone 3500 Vapour Blasting Equipment Vapor Honing Technologies

Vapor Blasting In Your Home Shop Vapor Honing Technologies Youtube

Vapor Honing Services What Is Vapor Honing And Does It Work

Vapor Blasting What It Is Costs And Shipping

Vapor Honing An Engine The Ultimate Guide

Cleaning Pistons Using Vapor Blasting Vapor Honing Technologies Youtube